About Laboratory

Our Nanotechnology Laboratory specializes in the synthesis of diverse nanomaterials with tailored properties. We employ a range of chemical methods including precipitation, hydrothermal, thermal decomposition, SILAR, photodeposition, and sol-gel techniques. Utilizing equipment such as furnaces, ultrasonic baths, centrifuges, ovens, and autoclaves, we achieve precise control over nanomaterial fabrication. This enables us to develop advanced materials for various applications. Our research focuses on exploring and optimizing nanomaterial synthesis for enhanced performance.

Our Mission

To synthesize diverse nanomaterials with controlled properties using a range of chemical methods, including precipitation, hydrothermal, thermal decomposition, SILAR, photodeposition, and sol-gel techniques, advancing fundamental knowledge and enabling technological innovations.

Our Vision

To be a recognized center of excellence in nanomaterial synthesis, renowned for our expertise in diverse fabrication methods and our contributions to developing advanced materials for various applications.

Spin Coater

For thin film deposition. Our spin coater allows us to create uniform thin films of nanomaterials on various substrates by precisely controlling the rotation speed and dispensing parameters.

Dip Coater

Our dip coater enables precise and controlled deposition of thin films by immersing substrates into a solution containing nanomaterials and withdrawing them at a controlled speed. This technique allows us to create uniform coatings with desired thicknesses for various applications, including sensors, solar cells, and optical devices.

Furnace

Our high-temperature furnaces provide precise temperature control for various nanomaterial synthesis processes, including thermal decomposition, annealing, and calcination. These furnaces enable us to achieve desired crystalline structures and material properties by subjecting precursors to controlled heating profiles.

Ultrasonic Bath

The ultrasonic bath utilizes high-frequency sound waves to create cavitation, effectively dispersing nanoparticles in liquids, promoting uniform mixing of reactants, and assisting in the deagglomeration of synthesized nanomaterials. This ensures homogeneity and improves reaction kinetics.

Centrifuge

Our high-speed centrifuges are essential for separating synthesized nanomaterials from reaction solutions. By applying centrifugal force, we can efficiently isolate and collect the desired nanomaterials, facilitating purification and further processing steps like washing and drying.

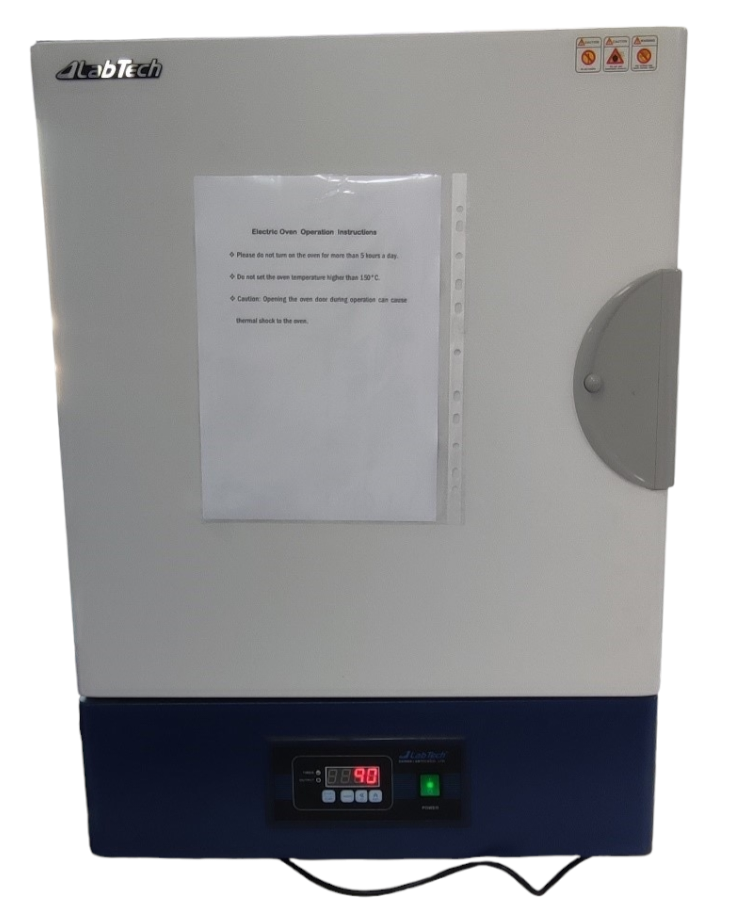

Oven

Our laboratory ovens provide controlled heating for drying synthesized nanomaterials, removing residual solvents, and performing low-temperature heat treatments. These ovens ensure consistent and uniform drying conditions, crucial for maintaining material integrity.

Autoclave

The autoclaves in our lab are used for hydrothermal synthesis, enabling reactions at elevated temperatures and pressures. This technique allows us to synthesize nanomaterials with unique morphologies and properties that are not achievable under ambient conditions. The controlled environment within the autoclave promotes crystal growth and phase formation.

Meet Our Team

Hossein Mahmoud Khojasteh

Operator of laboratory,I manage the Nanotechnology Lab, supporting researchers through training, troubleshooting, and optimized experimental design.

Publications

Our team has published numerous peer-reviewed articles in high-impact journals. For a full list of publications, visit our website.

Future Works

A) International Project: Industrial Scale Synthesis of Mesoporous Silica

Objective: Collaborate on a project based in Italy to scale up the synthesis of mesoporous silica for industrial applications, with a focus on optimizing production processes.

B) Industrialization of Nanoparticle Synthesis (CuO and ZnO NPs)

Objective: Lead efforts to industrialize the synthesis of copper oxide (CuO) and zinc oxide (ZnO) nanoparticles, improving production efficiency and consistency to meet industrial demands.

C) Design and Development of P-N Junction and Perovskite Solar Cells

Objective: Work on the design and fabrication of P-N junctions and perovskite solar cells, focusing on enhancing their energy efficiency and operational stability.

Contact Us

For inquiries, collaborations, or more information, email us at [email protected].